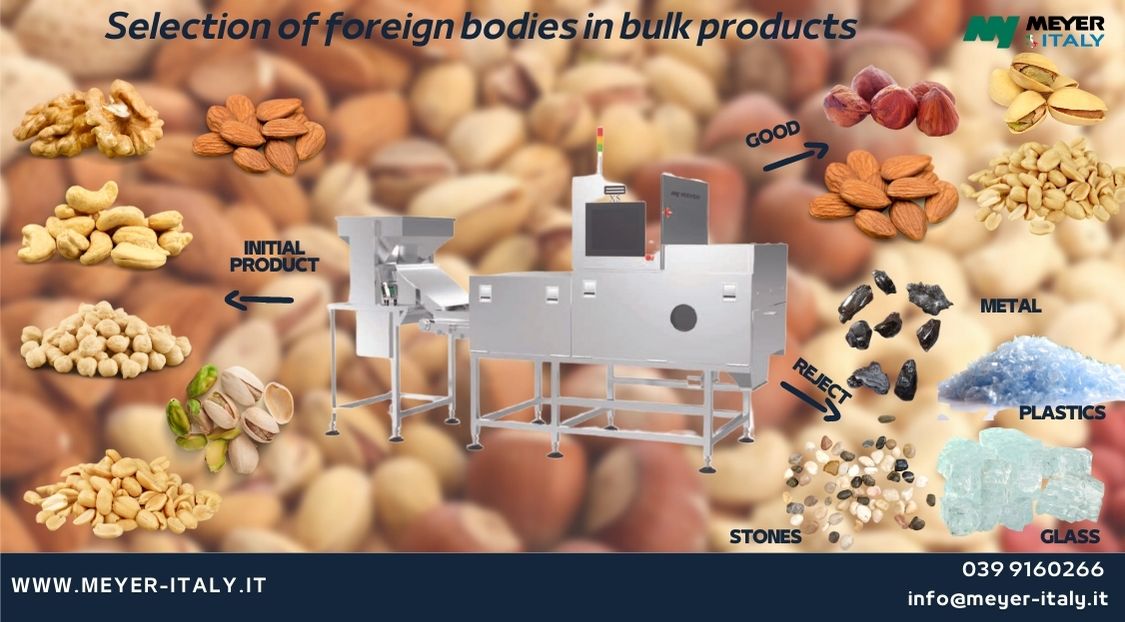

XS series X-ray sorter

It specializes in bulk product sorting to identify foreign products such as iron, glass, plastic and rubber. Its Meyer-patented MAGLEV 3.0 removal method pinpoints the defect for more precise defect removal.

The operator interface is simple and intuitive, designed to simplify all basic operations.